Setting new standards for materials testing

ASU researcher using NSF CAREER Award to develop methods to ensure perovskite solar panel reliability

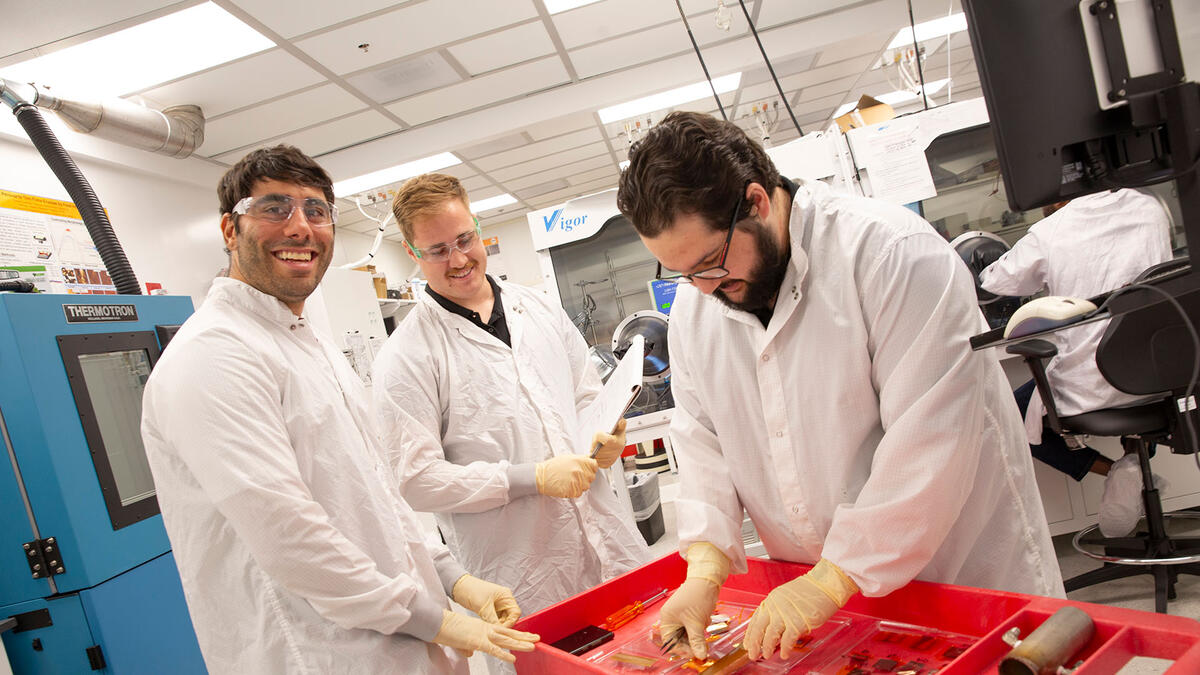

Nick Rolston (left), an assistant professor of electrical engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, conducts experiments in his lab with electrical engineering alumnus Hunter Mantle (center) and electrical engineering undergraduate student Jacob Burrows (right). Rolston received a 2024 National Science Foundation Faculty Early Career Development Program (CAREER) Award to explore durability standards for solar panels made from a class of materials called perovskites. Photo by Erika Gronek/ASU

In sunny parts of the world, solar panels seem to be everywhere.

The panels, typically made from silicon, provide an electricity source that produces no carbon emissions. While they are an important part of reducing society’s fossil fuel dependency, traditional solar panels aren’t without their drawbacks.

Silicon is difficult and expensive to use in manufacturing, requiring specialized machinery and facilities. There are also potential supply chain issues involved in manufacturing silicon, with most of the manufacturing and raw material harvesting taking place in China.

Perovskites are an emerging class of minerals with the potential to replace silicon as a solar panel material. The material is readily available and up to 10 times cheaper to produce than silicon, and manufacturing solar panels from perovskites requires minimal infrastructure. However, the requirements to build a reliable, long-lasting perovskite solar panel remain a mystery.

Nick Rolston, an assistant professor in the Ira A. Fulton Schools of Engineering at Arizona State University, has received a 2024 National Science Foundation Faculty Early Career Development Program (CAREER) Award to solve this mystery by developing standards for perovskite solar panel reliability and longevity.

Testing perovskite panel limits

Silicon solar panels have a standard lifespan of at least 25 to 30 years and a long history of standards for thermomechanical reliability. Thermomechanical reliability refers to parameters for materials holding up against physical strain, such as resistance to cracking in the face of strong winds, and sustaining damage under the temperature conditions the materials will face in operation.

Because silicon solar panels have been around for decades, standards to build high-quality panels are well established after years of research and testing. However, there are no such tests or standards for perovskite panels.

As a family of materials with different properties than silicon, perovskites exhibit much different behavior. Many designs developed to date degrade quickly, dropping to 80% of their original efficiency — the standard for replacement — after a year or less.

To alleviate perovskite solar panels’ rapid decline in function, Rolston, a faculty member in the School of Electrical, Computer and Energy Engineering, part of the Fulton Schools, aims to develop a standard for a series of lab tests that deduce which environmental factors are destabilizing the panels and quantify the degradation that occurs due to each factor.

“We want to find out within 25 days or 25 hours, ideally, if something is going to be long-lasting,” he says. “What are some tests we can do in the lab that take hours, days or weeks at most, that will predict the types of failures that would exist on the timeline of years or decades?”

To determine the perovskite solar panels’ degradation causes, Rolston and the students in his lab will determine which combinations of tests to put the panels through simultaneously.

“We can rip apart a material and see how much energy that takes,” he says. “But in real life, there are going to be different temperatures, sunlight and maybe hail and wind. We’re really trying to understand the synergistic effects of how mechanical properties interplay with environmental effects to create damage together.”

For example, a fracture test, which measures the force required to break a panel and creates the types of delamination that can occur after years of exposure in the field, can be combined with a test inside a chamber that rapidly heats and cools to mimic years of seasonal temperature swings. Together, the tests provide a more comprehensive assessment of a panel’s durability.

To complete the tests, Rolston will conduct work in his lab and the ASU Core Research Facilities, including the Solar Fab, Advanced Electronics and Photonics and Eyring Materials Center facilities.

Rolston will receive panel designs to test from an array of industry collaborators, including First Solar and ASU spinout company Beyond Silicon, supplying a variety of perovskite panel designs for testing.

Educating future engineers

In addition to the research component of the work, the CAREER Award funds workforce development and education efforts. Rolston’s plans include outreach to recruit women and Indigenous students from community colleges and tribal schools to attend ASU to conduct perovskite solar panel research.

“I was motivated to do this because, in the solar industry, over 90% of the executives are male,” Rolston says. “In terms of Indigenous communities, a huge amount of previous energy transitions have occurred at their expense. You’ll hear a lot of examples of how tribal lands are very close to polluted areas or in places where they don’t have access to energy.”

To retain and support these groups and other first-year graduate students once they’re at ASU, Rolston’s plans include provisions for a mentorship program in which experienced students offer guidance to newer students.

The work supported by the CAREER Award funding also includes global education efforts in perovskites for solar technology by adding a chapter on the minerals to pveducation.org, an online solar technology education website created by Christiana Honsberg, a Fulton Schools professor of electrical engineering with a joint appointment in ASU’s School for the Future of Innovation in Society, and Stuart Bowden, a former Fulton Schools associate research professor of electrical engineering.

Rolston credits receiving the award to mentorship from School of Electrical, Computer and Energy Engineering faculty members such as Honsberg and Zachary Holman, vice dean for research and innovation in the Fulton Schools and a professor of electrical engineering. Rolston says they have provided him tremendous amounts of support since he joined ASU in 2022. He says receiving the award would also not have been possible without the five doctoral students in his group who collected the preliminary data needed for the CAREER Award project proposal.

Creating a legacy for future materials testing

Once the project is complete, Rolston’s larger goal is to leave a legacy of testing standards for materials beyond perovskites and even for overall solar panel testing.

“Maybe it will be something with materials for quantum computers or superconducting materials,” Rolston says. “There are going to be different considerations, but we are trying to lay out a path to use these types of methods more broadly and to inform the development of new technologies going forward.”

More Science and technology

New ASU institute to create national cybersecurity hub

In 1788, 13-year-old Eugène-François Vidocq, the son of a wealthy merchant in Arras, France, stole his father’s set of silver plates. And so began a life of crime that resulted in dozens of…

From pizza pies to power plays: The rise of an engineering leader

Although he now holds the title of executive vice president of operations for Arizona Public Service Company, or APS, the largest electric company across the state, Jacob Tetlow had a humble…

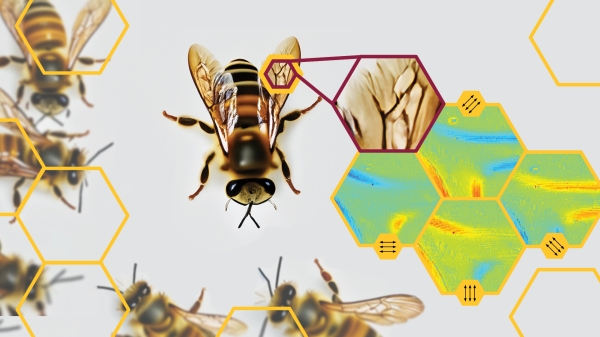

Quest for microscopy advances aims to boost high-tech capabilities

One method for seeing beyond the capabilities of the human eye is polarimetric imaging. However, the standard design of polarimetric microscopes is bulky, large and hard to use outside of a…